In a world where seamless connections are paramount, the Electric Terminal Riveting type emerges as a game-changer. This article delves deep into this revolutionary technology, exploring its various facets, applications, and the transformative impact it brings to the field.

Exploring the Basics of Electric Terminal Riveting Type

What sets it apart?

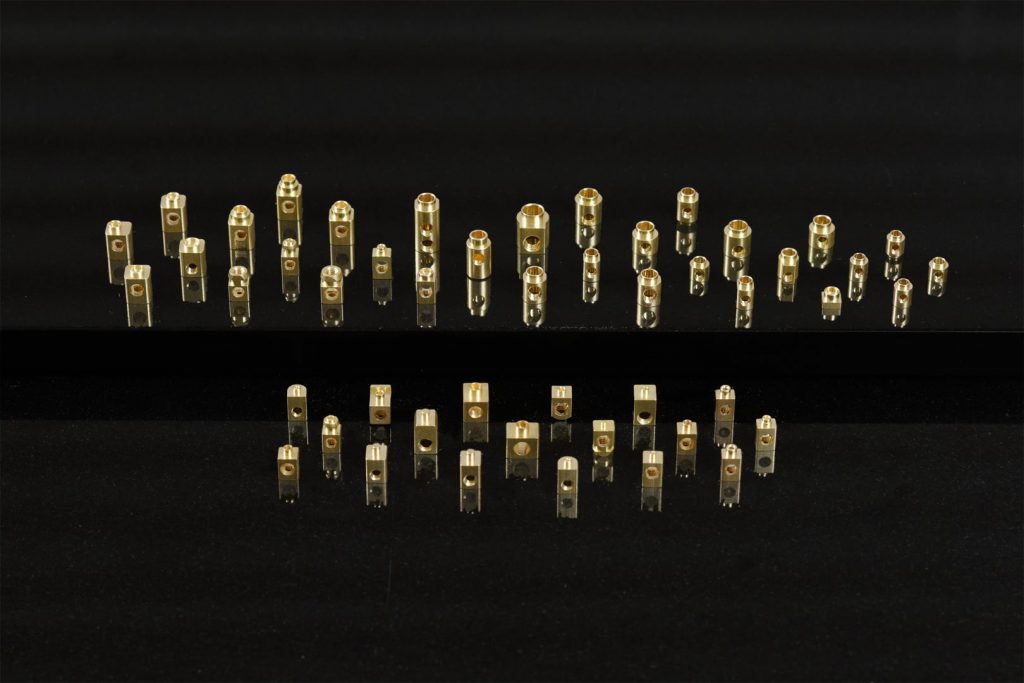

A cutting-edge method in electrical connections, goes beyond traditional techniques. Its innovative approach ensures secure, durable, and efficient electrical joints, elevating reliability and performance.

Applications Across Industries

in Automotive Engineering

In the realm of automotive engineering, the electric terminal riveting type finds widespread use. From intricate wiring in electric vehicles to robust connections in traditional automobiles, this technology guarantees precision and longevity.

Electric terminal riveting type in Aerospace Technology

Aerospace demands unparalleled reliability, and the electric terminal riveting type delivers. Ensuring steadfast connections in avionics and spacecraft, it plays a pivotal role in the safety and functionality of aerospace systems.

How Does It Work?

Understanding the riveting process

The electric terminal riveting type employs advanced riveting techniques, seamlessly joining terminals with precision. Through a combination of pressure and controlled electrical currents, a secure connection is formed, promising longevity and resilience.

Advantages Over Conventional Methods

Reliability and Durability

Unlike traditional soldering, the electric terminal riveting type eliminates the risk of weak joints. The riveted connections withstand environmental challenges, ensuring longevity and reliability in diverse conditions.

Efficiency in Mass Production

Industries benefit from the efficiency of the riveting process in mass production. Quick and precise, it enhances productivity without compromising on the quality of connections.

Electric Terminal Riveting Type in Action

A Real-world Perspective

Having worked extensively in the electrical engineering sector, I’ve witnessed firsthand the transformative impact of the electric terminal riveting type. Its precision and reliability have not only streamlined processes but also elevated the overall quality of electrical connections.

Electric Terminal Riveting Type: FAQs

How does the electric terminal riveting type differ from traditional soldering?

The electric terminal riveting type employs pressure and controlled electrical currents, ensuring stronger and more reliable connections compared to traditional soldering.

Can the riveting process be applied to delicate electronic components?

Yes, the process is adaptable, allowing for the secure riveting of delicate electronic components without compromising their integrity.

Is the cost-effective for small-scale operations?

While initial setup costs may be higher, the long-term benefits in reliability and reduced maintenance expenses make it a cost-effective choice even for small-scale operations.

What industries benefit the most from?

Automotive, aerospace, and electronics industries are among the primary beneficiaries due to the technology’s reliability and efficiency.

Does the riveting process contribute to environmental sustainability?

The produces minimal waste, contributing to environmental sustainability compared to processes involving soldering and other methods.

Can the riveted connections withstand extreme temperatures and conditions?

Yes, the ensures connections that can withstand a wide range of temperatures and environmental conditions, making it suitable for diverse applications.

Conclusion

As we embrace the era of advanced connectivity, the electric terminal riveting type stands as a beacon of reliability and innovation. From automotive engineering to aerospace technology, its impact resonates across industries, promising a future where connections are not just made but made to last.